×

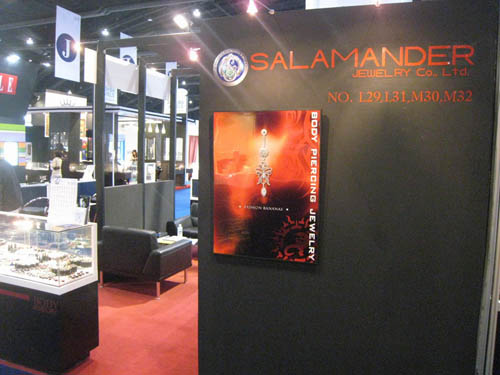

- Body Jewelry

- ball closure rings

- barbells and tongue rings

- belly button rings

- body spirals and twister rings

- chains

- circular barbells

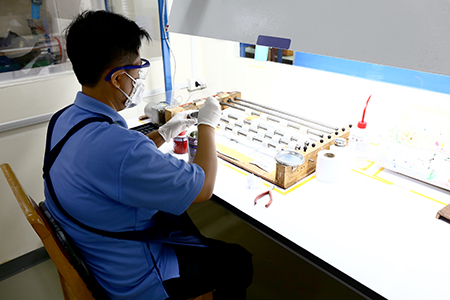

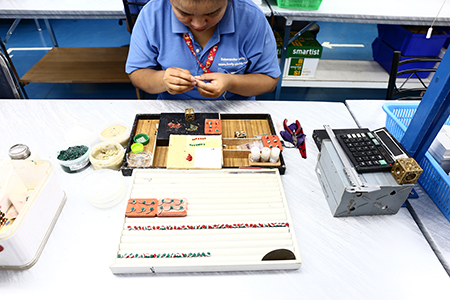

- cleanroom and medical supplies

- curved micro barbells

- dermal anchors

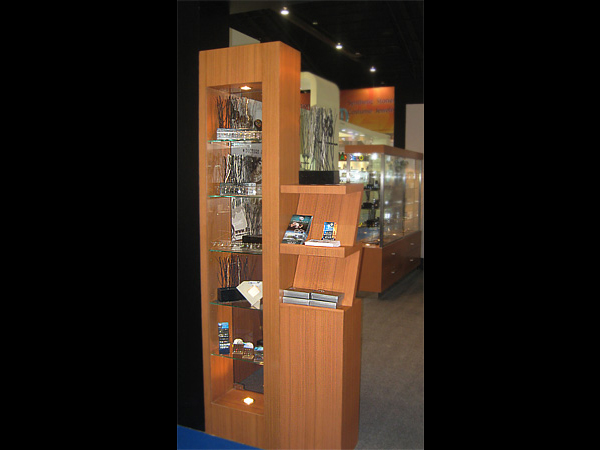

- displays

- ear spirals claws fish hooks

- fake piercings jewelry

- hinged rings and clickers

- intimate piercing

- labret piercings

- loose balls and attachments

- loose pins

- nipple piercing

- nose rings and studs

- piercing sets

- plugs and tunnels

- seamless rings

- septum jewelry

- sterile piercing

- threadless

- tragus and helix piercing

- Jewelry by Material

- Stainless Steel Jewelry

- Silver Jewelry

- Fashion Jewelry

- CLEARANCE SALE

- บริการเคลือบสีผิวงาน (Coating Services)

- New Arrivals

- Login

- Register

- Contact Us